Pipe Casing Spacers & End Seals: Essential Solutions for Secure, Efficient, and Long-Lasting Installations

At Fxeer Engineering Services, we understand the importance of high-quality, reliable products in every aspect of your construction and pipeline projects. That’s why we offer top-of-the-line Pipe Casing Spacers and End Seals to ensure the integrity, safety, and longevity of your pipeline systems. These products are specifically designed to provide a secure, smooth, and long-lasting solution for managing and protecting pipelines in various environments

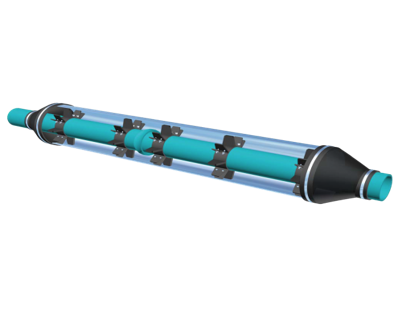

Pipe Casing Spacers: Reliable Support for Your Pipeline Systems

Pipe Casing Spacers are essential for maintaining proper alignment and protecting pipes during installation within casing pipes. These spacers help prevent pipe deformation and ensure that pipes are kept in the correct position throughout the pipeline installation process. They provide critical support, improve flow efficiency, and protect pipelines from corrosion and other environmental factors.

Key Features of Pipe Casing Spacers:

- Enhanced Alignment & Support: Our casing spacers keep pipes properly aligned within their casings, preventing sagging or misalignment that could lead to costly repairs or system failures.

- Corrosion Resistance: Made from durable, corrosion-resistant materials such as PVC, stainless steel, or composite plastics, our spacers offer long-term protection in harsh environments, ensuring the pipe’s integrity.

- Easy Installation: These spacers are easy to install, offering quick, secure placement during pipeline construction or maintenance projects, saving time and effort.

- Durability: Designed to withstand extreme environmental conditions—whether underground, underwater, or in other challenging conditions—our spacers ensure the long-term reliability of your pipeline systems.

- Non-Metallic Options Available: Our non-metallic casing spacers are perfect for reducing the risk of electrolytic corrosion when used with metal pipes.

Applications:

- Underground Pipeline Installations: Ideal for water, wastewater, oil, gas, and other pipeline applications.

- Construction Projects: Used for both new pipeline installations and the maintenance of existing pipelines.

- Infrastructure Projects: Critical in urban and industrial pipeline systems where alignment and protection are key.