Hydraulic Seals & Rotary Seals: Precision Engineered Sealing Solutions for Advanced Industrial Applications

At Fxeer Engineering Services, we deliver cutting-edge sealing solutions designed to enhance the performance, longevity, and reliability of your hydraulic and rotary systems. With decades of combined engineering expertise, our Hydraulic Seals and Rotary Seals are engineered to meet the most stringent industry standards, offering advanced protection for critical components in high-pressure, high-temperature, and dynamic environments. Whether you’re in the oil & gas, manufacturing, automotive, or aerospace sectors, our seals are built to withstand the toughest conditions and ensure that your equipment operates at peak efficiency.

Hydraulic Seals: Precision Sealing for High-Pressure Fluid Systems

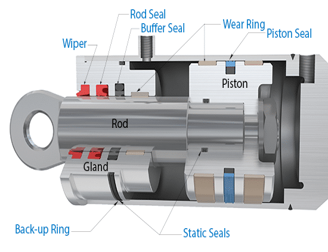

Hydraulic Seals are a fundamental component in maintaining the integrity of hydraulic systems by preventing fluid leakage and maintaining pressure. These seals are engineered to ensure optimal sealing performance in a wide range of hydraulic applications, from heavy-duty construction equipment to complex industrial machinery. Designed to accommodate extreme operating conditions such as high pressure, temperature fluctuations, and aggressive chemicals, our hydraulic seals provide the leak-proof and durable performance essential for minimizing downtime and ensuring the safe, efficient operation of your systems.

Key Features of Hydraulic Seals:

- Superior Leak Prevention: Hydraulic seals provide reliable sealing solutions to prevent both internal and external leakage, ensuring that the fluid remains contained under pressure, optimizing system performance, and reducing the risk of contamination.

- Pressure Resistance: These seals are meticulously designed to handle high-pressure environments, ensuring effective sealing even in systems operating at pressures ranging from low to ultra-high levels, providing consistent reliability across industries.

- High-Temperature Performance: Our seals are engineered to withstand the high-temperature environments commonly encountered in hydraulic systems, offering thermal stability even in temperatures exceeding 200°C (392°F), while maintaining their elasticity and sealing properties.

- Abrasion & Chemical Resistance: Manufactured using advanced elastomers and composite materials, our seals exhibit exceptional resistance to wear, abrasion, and corrosion, ensuring a long service life even in the presence of harsh chemicals, oils, and other aggressive fluids.

- Customization for Optimal Fit: We offer a wide variety of hydraulic seals, including O-rings, piston seals, rod seals, and wiper seals, available in numerous sizes, profiles, and materials. Our engineers work with you to determine the perfect fit for your application, ensuring superior sealing performance.

Applications:

- Heavy Machinery: Ideal for excavators, bulldozers, cranes, and other earthmoving equipment, ensuring reliable hydraulic system performance even under extreme loads.

- Industrial Equipment: Essential for pumps, valves, and hydraulic cylinders in industrial applications, including power generation, material handling, and robotics.

- Automotive & Aerospace: Used in hydraulic steering, braking systems, and flight control systems to provide efficient, long-lasting sealing and leak prevention.

- Agricultural Machinery: Designed for use in agricultural equipment like tractors, harvesters, and irrigation systems, where high-pressure and environmental exposure are common.

Rotary Seals: Advanced Sealing Solutions for Rotating Shafts and Dynamic Systems

Rotary Seals, also known as shaft seals, are engineered to prevent fluid leakage and contamination in systems that involve rotating shafts. These seals are critical for ensuring the smooth operation of rotating machinery, protecting both the shaft and surrounding components from damage caused by fluid loss or contamination. With a focus on reducing friction, wear, and energy loss, our rotary seals provide dynamic sealing solutions that optimize the performance of machinery subjected to continuous rotational motion.

Key Features of Rotary Seals:

- Dynamic Sealing Technology: Rotary seals are designed to provide an effective seal even while the shaft is in motion. With a superior dynamic sealing surface, they minimize leakage while reducing friction and wear on both the seal and the shaft.

- Contamination Protection: In rotating systems, contaminants such as dirt, dust, and moisture can compromise system integrity. Our rotary seals protect your equipment from these elements, ensuring clean operation and reducing the risk of component damage or failure.

- Low Friction & Energy Efficiency: Our seals are designed with low friction materials to minimize energy loss, reduce wear, and extend the lifespan of machinery. This makes them particularly valuable in high-precision applications where efficiency is critical.

- Temperature & Chemical Resistance: Rotary seals are crafted from advanced elastomers and PTFE compounds that exhibit excellent performance across a wide range of temperatures, from cryogenic to over 250°C (482°F), and are resistant to a variety of chemicals, oils, and fuels.

- Enhanced Durability: With materials that can withstand extreme pressures, temperatures, and environmental conditions, our rotary seals are designed for high-performance, even in the harshest industrial and automotive applications.

Applications:

- Pumps & Compressors: Used extensively in the sealing of rotating shafts in fluid and gas pumps, as well as compressors in HVAC, refrigeration, and industrial applications.

- Gearboxes & Transmissions: Essential for ensuring the effective sealing of rotating shafts in gearboxes, motors, and other rotary equipment, preventing oil leakage and contamination while improving system performance.

- Hydraulic and Pneumatic Systems: Rotary seals are critical in both hydraulic and pneumatic systems, where high-speed rotational movement must be sealed effectively without compromising system pressure or integrity.

- Automotive & Aerospace: Found in rotating components of automotive engines, turbochargers, steering systems, and aerospace applications, ensuring continuous, reliable operation under extreme conditions.

Why Choose Fxeer Engineering Services for Hydraulic and Rotary Seals?

- Engineered for Excellence: Our seals are designed and manufactured with the highest precision, utilizing advanced materials and state-of-the-art manufacturing techniques to provide optimal sealing performance in even the most demanding applications.

- Customization to Meet Specific Needs: We work closely with you to provide tailored sealing solutions that address the unique challenges of your systems, whether it’s extreme pressure, temperature fluctuations, or chemical exposure.

- Global Industry Experience: With expertise spanning diverse industries, including automotive, aerospace, oil & gas, construction, and manufacturing, our seals are trusted by engineers and operators worldwide for their reliability and performance.

- Long-Lasting Protection: Built with durability in mind, our hydraulic and rotary seals are designed to extend the operational lifespan of your machinery, reducing the need for frequent maintenance and minimizing downtime.

- Dedicated Technical Support: Our engineering team offers expert guidance in selecting the right seal for your specific application, providing in-depth product knowledge, installation advice, and after-sales support.

Get in Touch with Fxeer Engineering Services

At Fxeer Engineering Services, we are committed to providing high-performance Hydraulic Seals and Rotary Seals that deliver exceptional sealing solutions for your most demanding applications. With a focus on quality, durability, and customization, we ensure that your systems remain leak-free, efficient, and reliable throughout their lifecycle.

Contact us today to discuss your specific sealing needs, request a quote, or consult with our expert engineers on finding the best sealing solutions for your projects. We are dedicated to ensuring the performance, protection, and longevity of your machinery and systems.